PRECISION AND ACCURACY ABOVE ALL

AEROSPACE

We provide 3D dimensional inspection consultancy and products related to the metrology industry

Civil and military aviation demand precise dimensional inspection control. This inspection ensures that assembly jigs, components, and assembly parts meet the manufacturer's specifications. Correlating measurements between the produced part and the designed one is crucial for maintaining tolerance and ensuring the safety of flying.

ALTO is a renowned leader in the industry, with a proven track record of expertise in civil aviation and rotary wings sectors. Our specialized offerings encompass a comprehensive range of services, including dimensional inspection, designing assembly jigs, automating measurement processes, and providing seamless support for assembling and composite lay-up processes. We take pride in our meticulous First Article Inspection (FAI) and non-compliance management. With cutting-edge photogrammetric systems, we ensure precise alignments for satellite and radio telescope antennas. Moreover, our specific consultancy services cater to clients seeking innovation in their manufacturing processes. Partner with ALTO for top-tier dimensional inspection and metrology solutions, guaranteeing uncompromising quality in the civil aviation and rotary wings sectors.

AUTOMATED INSPECTIONS

Aerospace production requires accurate and fast measurement solutions.

Most of the aircraft are nowadays manufactured using carbon fiber. These parts are light, large, and do not require Stationary CMM accuracy for inspection.

At ALTO, we develop automation solutions to inspect parts and assemblies.The automation can be divided into:

- Fully automated

- Semi-automated

JIG CALIBRATION

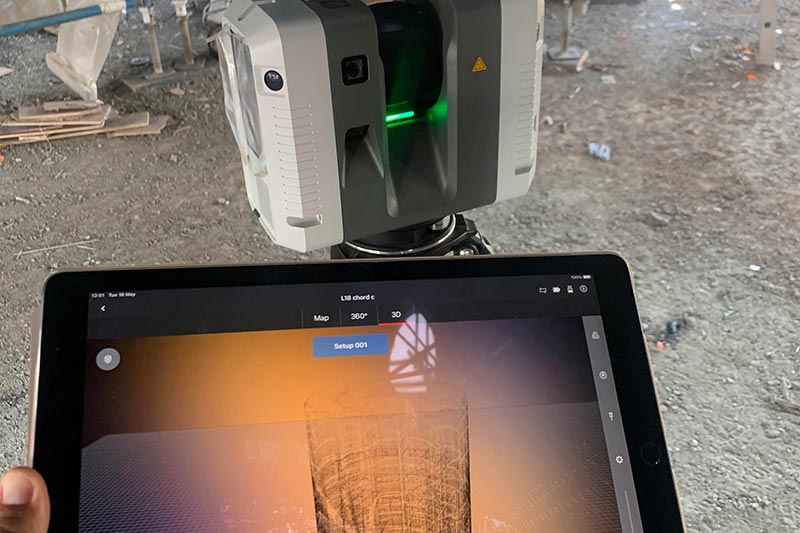

ALTO owns portable equipment such as laser tracker and portable arms to perform on-site dimensional inspection. We can support You providing engineer, equipment and software or the engineer only when You need. Most of our aerospace client has a maintenance contract with Us to measure and maintain the jigs. This is a yearly activity and for the client is better to rely on a supplier to manage the pick of work and manage the jig and fixture measurements and rectification.

FLYING PARTS INSPECTIONS

Portable measuring devices are widle useded during manufacturing assembly maintance and mificiation of aircraf or single flying parts.

The measuring volume of a portable equipment is variable the portability add all the flexibility a company need during manufacturing or assembly.

CMM PROGRAMMING AND SPECIAL SOLUTIONS

ALTO program and measure parts under CMM using PC-DIMIS and Polyworks.

At Alto we can implement also statist analysis using q-das, and supply CMM operator and trainer. ALTO can design fix-jigs and fixture and also movable one connected to the CMM controller. Some carbon fiber parts can be deformed as per Boeing and Airbus procedure to simulate the installation. ALTO design moveable jig that apply the right amount of pressure reading the CMM measurements. The amount of force applied is reported at each measurement where necessary.