PRECISION AND ACCURACY ABOVE ALL

AUTOMOTIVE

We provide 3D dimensional inspection consultancy and products related to the metrology industry

Automotive requires mostly automated solution to inspect the parts and product during mass production. However during prototyping and fixture and mould verification a Laser tracker or a Romer ARM are the right equipment to perform dimensional inspect.

With an extensive background in the automotive industry, ALTO offers comprehensive metrology services that encompass all aspects of automotive production. Our expertise includes 3D inspection and calibration of jig fixtures and moulds, ensuring precision and efficiency in manufacturing processes. We excel in designing, manufacturing, and calibrating metrology fixtures, as well as welding fixtures, tailored to your specific needs. Our automated inspection solutions, integrated with state-of-the-art scanners or blue light technology, seamlessly collaborate with robots for optimal productivity and accuracy. Additionally, we provide specialised metrology solution development and training, empowering your team with the knowledge and skills to utilise cutting-edge technology effectively. Trust ALTO for top-tier metrology services, driving excellence and innovation in the automotive industry.

WELDING STATION

Automotive production line require accurate dimensional inspection during fabrication installation and maintenance.

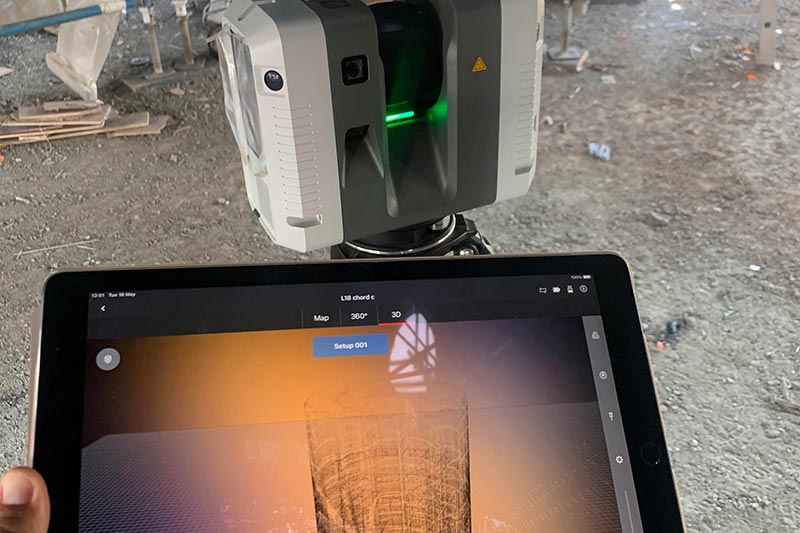

ALTO has the experience, instruments and engineer to support OEM and supplier during manufacturing installation and maintenance activity of automated production line.

CHECKING FIXTURE

ALTO execute on-site fixture and jig calibration using portable equipment.

Laser tracker and Faro or Romer ARM are the most used equipment to calibrate small and large jig and fixture in the automotive industry.

BIW INSPECTION

BIW dimensional inspection are typically fully automated. ALTO design and program automated solution using probing or scanning devices.

The growing need to develop electric cars from body donor vehicles, it is necessary to carry out measurements during the prototyping phase. Typically these measurements are performed with portable instruments such as Hexagon Laser Trackers and Romer ARM.

AUTOMATION

Efficient automation has significantly increased production capacity. Metrology, the link between the real and virtual worlds, must necessarily be efficient and the measurements must be performed quickly and the result immediately accessible.

Furthermore, it is more and more important to acquire a significant amount of data because intelligent manufacturing is based on the ability to acquire and use data within processes. ALTO solutions support fully automated measurement and process controls for both probing and scanning.