PRECISION AND ACCURACY ABOVE ALL

ON SITE MACHINE ALIGNMENT

We provide 3D dimensional inspection consultancy and products related to the metrology industry

On-site machines play a crucial role in various industries, including wind farms, shipbuilding, Oil & Gas, and energy sectors.

They are utilised to machine surfaces, bearing housings, drill holes, and much more, providing efficient solutions for critical projects.

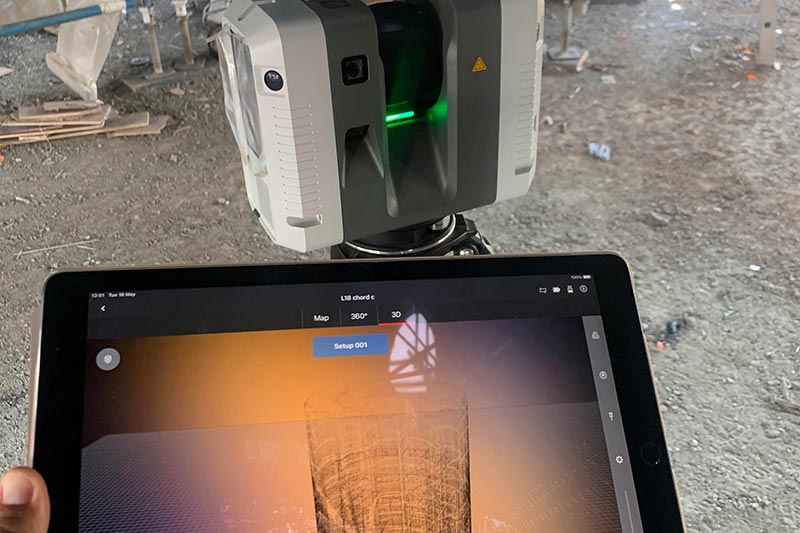

At ALTO, we offer comprehensive support for on-site machine activities with our Laser Tracker services. Our Leica laser trackers, powered by batteries, are the perfect equipment to ensure precision and accuracy before, during, and after machining processes.

With ALTO’s advanced metrology solutions and expert engineers, we guarantee reliable dimensional inspection for on-site machining, optimising your project’s performance and ensuring top-notch results. Trust us to deliver excellence and efficiency in on-site machining, enabling smooth operations and successful outcomes across various industries

The software we use supports virtual assembly, a crucial analysis that saves time and resources during the fit-up stage.

FLANGE MACHINING

Ensuring flange planarity and bolt hole position accuracy is crucial for achieving a proper and secure fitting. On-site machining is an accurate process that relies on the guidance of a laser tracker to swiftly position the machine in relation to the DATUM.

At ALTO, our laser trackers precisely position the CNC head, maintaining tolerances during machining, and accurately measuring and reporting the tolerances upon completion of the machining process. Our expert engineers and advanced metrology solutions guarantee seamless on-site machining, delivering reliable results and impeccable fitting for your critical projects.

Trust ALTO to optimise your on-site machining operations with our state-of-the-art laser tracker technology, elevating the precision and efficiency of your machining processes.

PUMP CASE MACHINING

Dredger pump maintenance involves rebuilding worn-out materials and on-site machining to reconstruct the pump-to-shaft interface.

At ALTO, we ensure precise measurements of the build-up material before machining, and our on-site CNC is accurately aligned with a laser tracker. This alignment significantly reduces dredger pump repair time and enhances overall efficiency.

With ALTO’s expert engineers and advanced metrology solutions, we guarantee seamless and reliable dredger pump maintenance.

BEARING HOUSING

When it comes to on-site machining of bearing housings, shafts, and gearboxes, precision is key. To position the machining bar accurately, a laser tracker is essential.

Frequently, the reference is another bore, and maintaining a precise distance is crucial for successful machining. At ALTO, we provide the most efficient solution by using a laser tracker to align and position the machining bar precisely.

Our expert engineers and advanced metrology solutions ensure seamless on-site machining, optimising the alignment process and guaranteeing superior results. Trust ALTO for top-tier dimensional inspection and alignment services, elevating the efficiency and accuracy of your on-site machining projects.

PCD MARCHING

At ALTO, we understand the importance of precise marking for on-site drilling. Our expert engineers utilise laser trackers and real-time tracking to swiftly mark, verify, and report the hole centres.

With ALTO’s advanced metrology solutions, hole centres are quickly marked with benchmark accuracy within 0.1mm. Our laser trackers ensure superior precision, allowing for efficient and accurate on-site drilling.

We are committed to delivering excellence and efficiency in every aspect of your on-site operations, ensuring successful outcomes for your critical projects.